What can you expect?

Prusament PA11 Carbon Fiber Black is our own in-house made Polyamide filament filled with carbon fibers. The whole manufacturing process is closely monitored and tested - we guarantee ±0.04mm precision and highly-consistent colors.

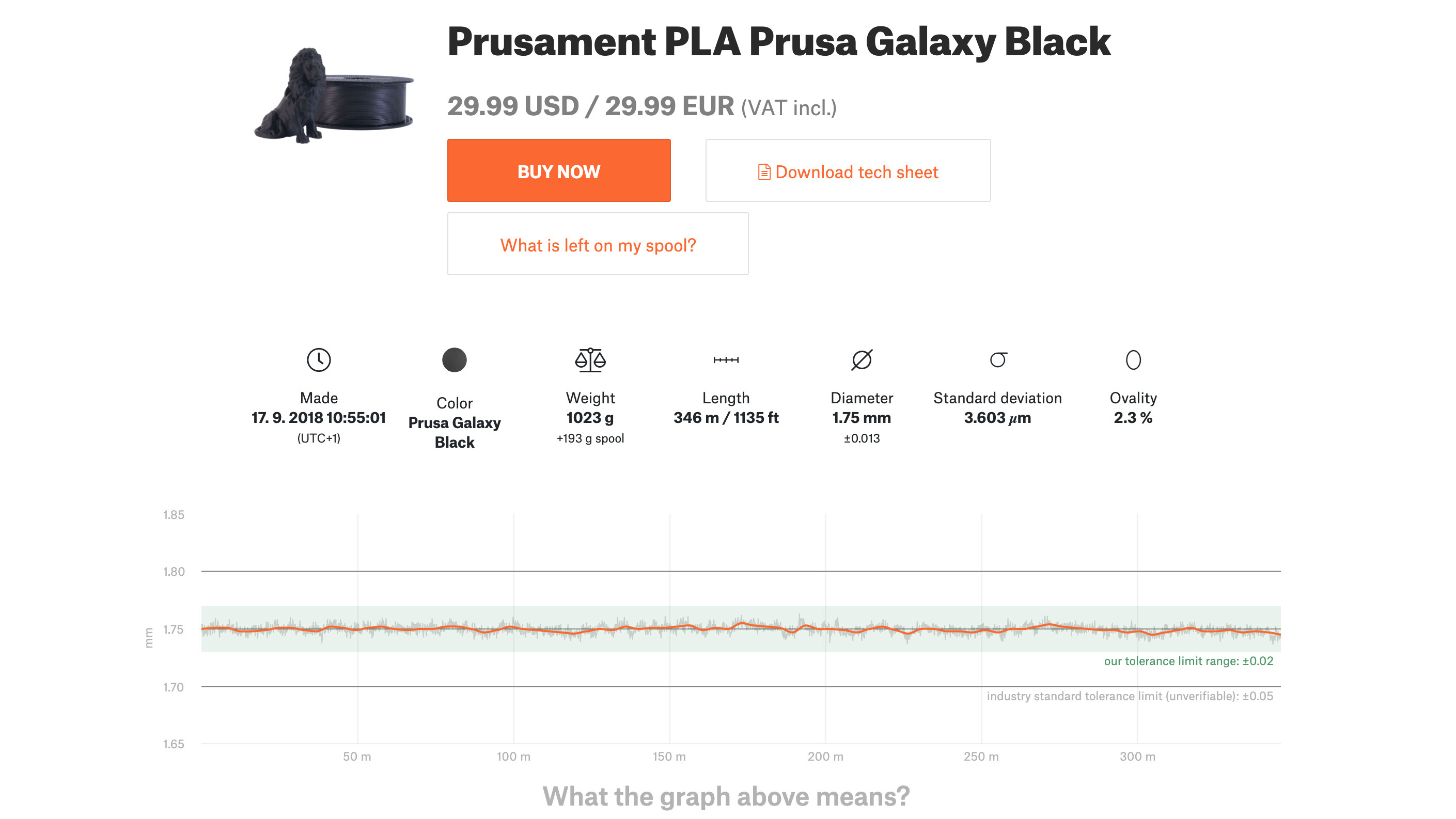

You can inspect the parameters of every spool we made at prusament.com. Check the sample spool!

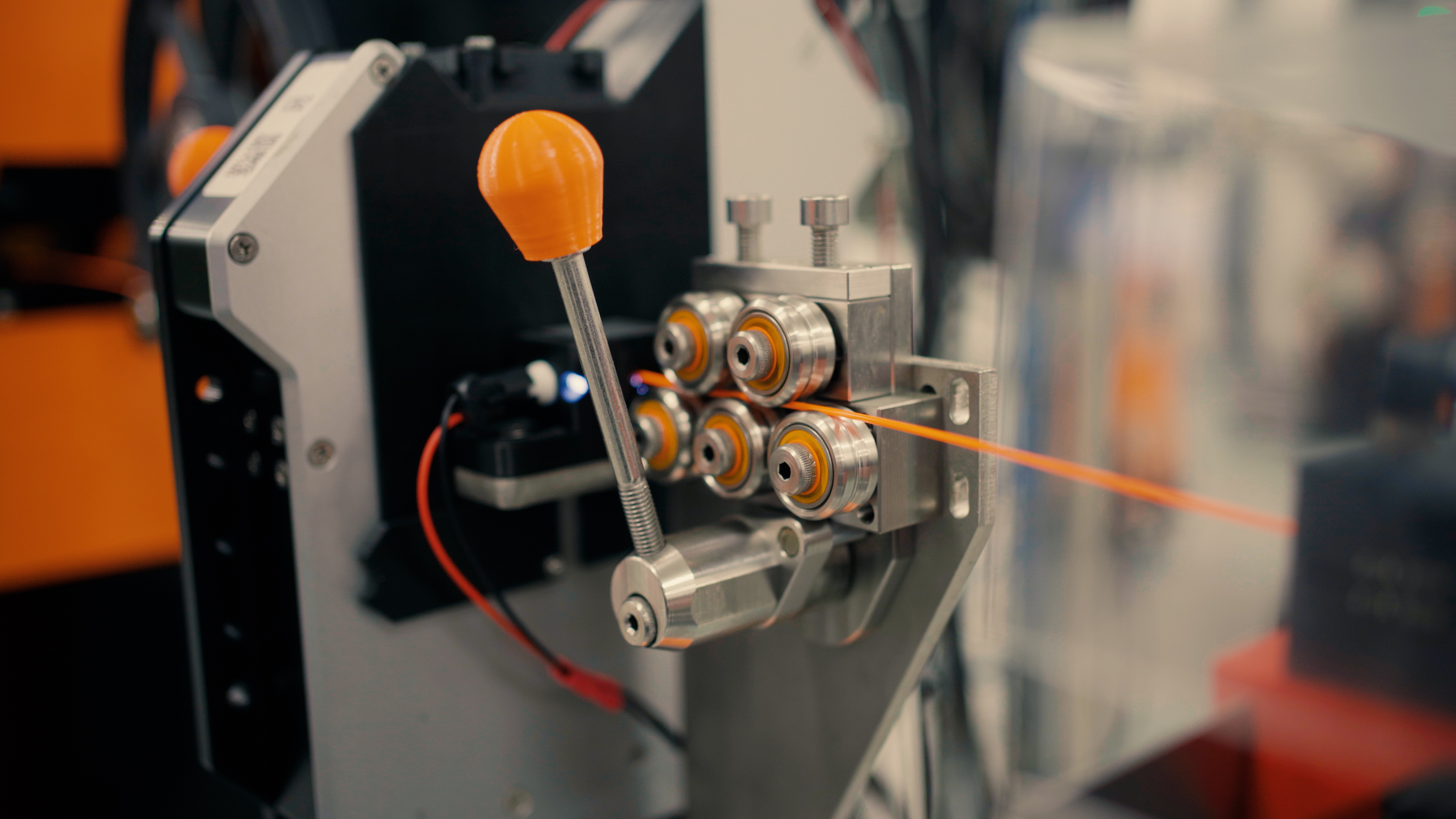

Manufactured In-House By Josef Prusa

We were not satisfied with the quality of filaments on the market. So we decided to make our own! Prusa Research is the only 3D printer manufacturer with its own filament production.

Premium-Grade Materials And Thorough Testing

The whole manufacturing process is closely monitored and tested – string diameter, color consistency, and mechanical properties – to make sure that every spool is perfect.

± 0.04 mm Manufacturing Guaranteed Precision

We believe the industry standard of 0.05 mm isn’t sufficient for perfect 3D printing. Instead, we guarantee ±0.04mm precision and highly-consistent colors in our filaments.

High Quality You Can Check Yourself

We are the only manufacturer that gives the option to inspect parameters of every filament spool. Scan a QR code on the spool to see all details online (check the sample spool).

Read more about Prusament in general in the article at blog.prusa3d.com and about Prusament PA11 Carbon Fiber Black in this article. Or just visit Prusament.com!

About PA11 Carbon Fiber Black

Prusament PA11 (Nylon) Carbon Fiber is an ideal filament for prototypes in the automotive, aerospace, and hobby industries, given its excellent resistance to heat, chemicals, and mechanical stress. Among the Prusament filaments, PA11-CF has by far the best temperature and chemical resistance. 3D-printed parts withstand up to 190 °C (depending on stress) and have increased resistance to many solvents (NaOH, Methanol, Ethanol, Toluene, Acetone, motor oils, benzene, diesel, etc.). PA11-CF is a material made from castor oil, the carbon fibers used for this material are recycled, the same as for the Prusament PC Blend Carbon Fiber. The best use of the PA11-CF is for making special chemically, mechanically, and heat-stressed parts, such as car engine components.

Printing Setup

| Nozzle | 285±10 °C |

| Heatbed | 110±10 °C |

| Recommended print sheet | Special PA Nylon sheet |

Basic Attributes

| Excellent temperature resistance (up to 190 °C) | A special print sheet (or separation layer) is required | ||

| Great chemical resistance | Requires hardened nozzle | ||

| High impact and wear resistance (very strong and rigid material) | Lower layer-to-layer adhesion compared to pure PA11 | ||

| Low friction coeficient | Slightly hygroscopic (absorbs moisture) | ||

| Noticeably less hygroscopic compared to other polyamides | Emits odors during printing | ||

| Visually appealing matt black surface | |||

| Great dimensional stability – possible to print large models without an enclosure | |||

| Uses recycled carbon fibers from the manufacturing process |

Beginners tips & tricks

It is necessary to use a hardened steel nozzle. Carbon fibers are a highly abrasive material and may damage brass nozzles.

Prusament PA11 Carbon Fiber Black can be printed onto textured or satin print sheets with a thin separation layer made with a glue stick (a separation layer is extremely important). However, the results may not be perfect. This is why we are introducing a new type of sheet - the Double-sided Powder-coated PA Nylon Satin Spring Steel Sheet which was designed specifically for Prusament PA11 Carbon Fiber Black.

If you are using the new PA Nylon Satin sheet, never clean it with IPA, acetone, or other solvents - the surface will deteriorate quickly. Instead, clean the sheet with water only (a drop of dishwashing detergent may be used to clean greasy areas).

We recommend printing in a well-ventilated room because PA11 with carbon fibers may release a noticeable odor into the air and produce ultra-fine particles. Printing on an enclosed 3D printer helps contain the odors and particles, plus the increased temperature may improve layer-to-layer adhesion.

PA11, like other polyamides, is a hygroscopic material (it absorbs air moisture). If the absorbed humidity reaches high values, the print quality will deteriorate. Deterioration occurs after a few days to a month, but if you are unsure or know you have not printed for a long time, we recommend drying the filament at 90°C for 4-6 hours before printing.

You can find more in-depth printing tips in our article at blog.prusa3d.com and in our Material table.

Notes

Prusament PA11 Carbon Fiber Black is made in-house by Prusa Research.

1.75 mm filament is manufactured with a precision of ±0.04 mm.

Carbon fibers inside the filament are made by recycling waste from the manufacturing process or from carbon composites after the end of their lifespan.

Reviews

The Seller does not verify whether the published reviews come from consumers who have actually used or purchased the products or digital content or service. Reviews are provided by registered PRUSA ACCOUNT users.