What can you expect?

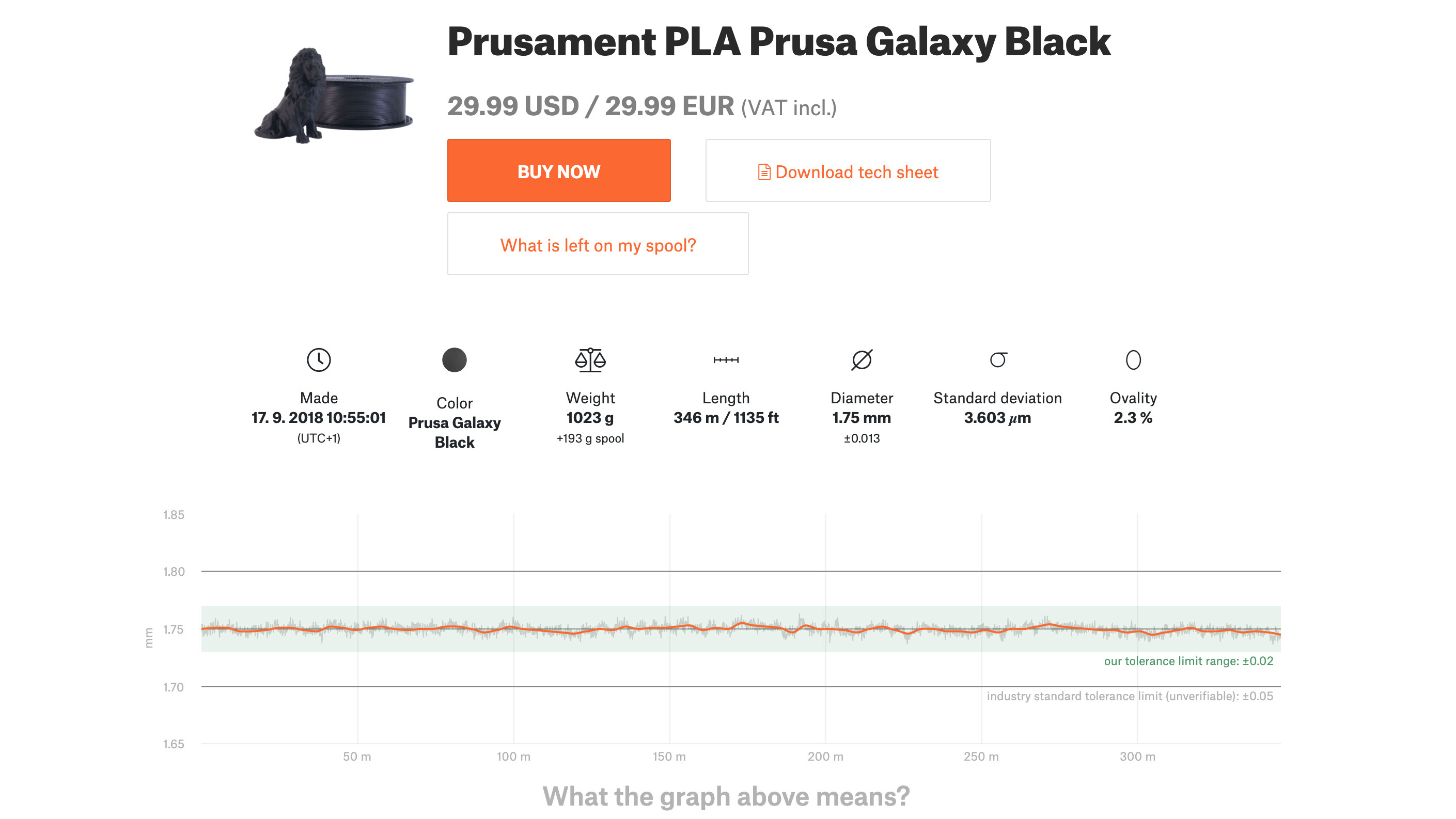

Prusament ASA is our own in-house made filament. The whole manufacturing process is closely monitored and tested - we guarantee ±0.03mm precision and highly-consistent colors. You can inspect the parameters of every spool we made at prusament.com. Check the sample spool!

Manufactured In-House By Josef Prusa

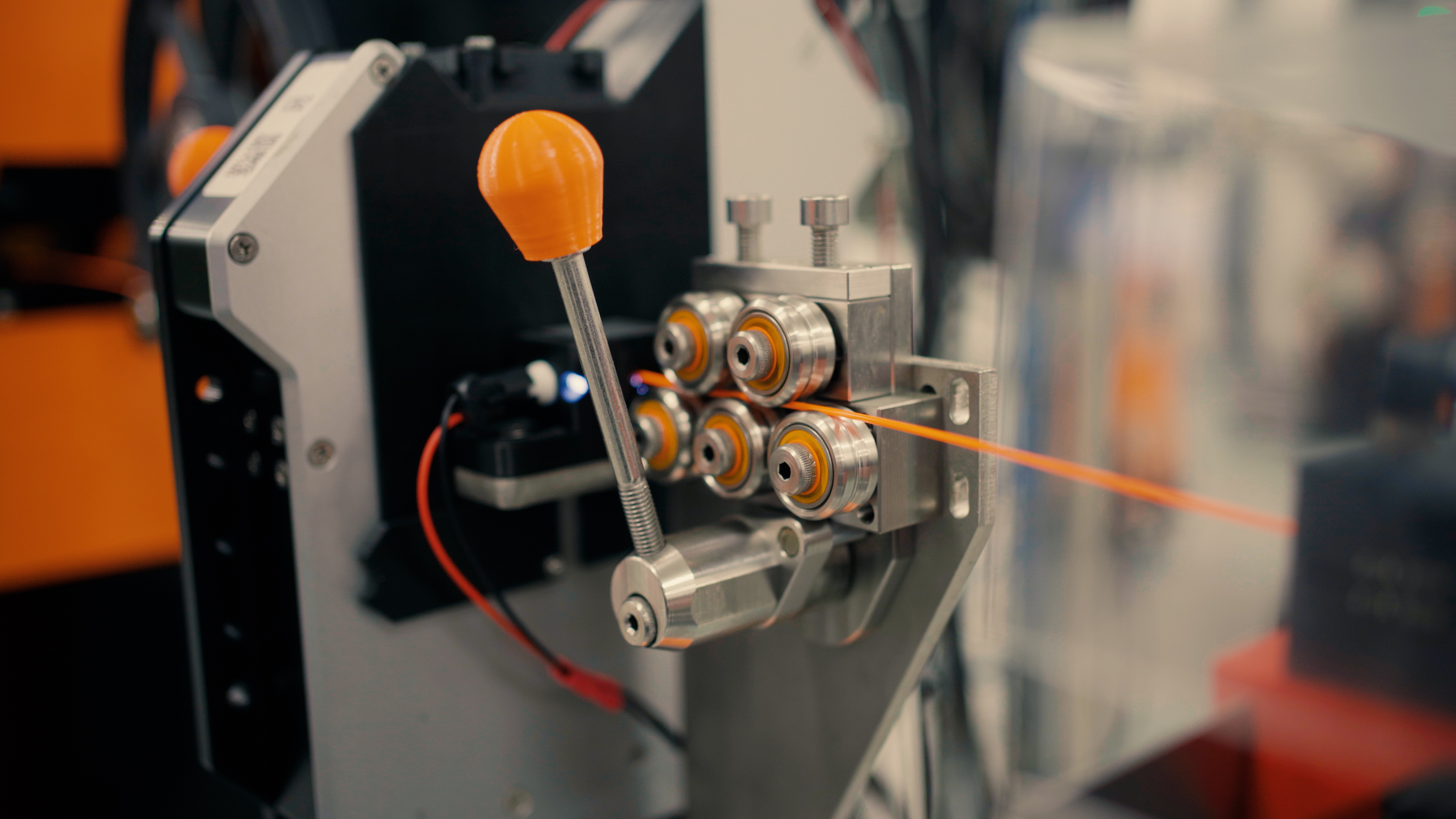

We were not satisfied with the quality of filaments on the market. So we decided to make our own! Prusa Research is the only 3D printer manufacturer with its own filament production.

Premium-Grade Materials And Thorough Testing

The whole manufacturing process is closely monitored and tested – string diameter, color consistency, and mechanical properties – to make sure that every spool is perfect.

± 0.03 mm Manufacturing Guaranteed Precision

We believe the industry standard of 0.05 mm isn’t sufficient for perfect 3D printing. Instead, we guarantee ±0.03mm precision and highly-consistent colors in our filaments.

High Quality You Can Check Yourself

We are the only manufacturer that gives the option to inspect parameters of every filament spool. Scan a QR code on the spool to see all details online (check the sample spool).

Read more about Prusament in general in the article at blog.prusa3d.com and about Prusament ASA in this article. Or just visit Prusament.com!

About ASA

ASA can be considered a true successor to ABS. Compared to ABS, it’s UV stable, it doesn’t suffer from shrinking so badly and the fumes produced are much less noticeable. ASA 3D prints are durable, tough and suitable for a wide range of applications. The solidification temperature is also higher compared to PLA and PETG, which gives objects printed from ASA an excellent temperature resistance – there are no signs of deformation up to temperatures near 93 °C. Thanks to all these properties, ASA is especially suitable to print objects meant for long-time outside use.

However, you can still encounter some issues related to shrinking (warping) of the material – especially when printing larger models. Even with the heatbed set to 110°C, the prints can shrink and warp, causing them to detach from the print bed. However, the effects are much less severe compared to ABS. This issue can be eliminated by printing inside an enclosure or by adding a tall skirt around the object.

ASA printing requires specific conditions for successful results. It’s important to run the prints in a well-ventilated room, because the material releases fumes and substances that could pose a potential health risk. However, when ventilating the room, do not create a draft around the print – this will negatively impact the result.

Print sheet preparation

For ASA printing, we recommend using the satin spring steel sheet. With the powder-coated or smooth sheet, the adhesion of the material can be too strong, which could potentially result in damage to the surface of the sheet. The textured and PEI smooth spring sheet preparation is easy: simply clean the surface with isopropyl alcohol and apply glue. To remove the print, wait until it cools down – it will then pop off easily.

You can find more details about printing with ASA in our in-depth article.

Printing Setup

| Nozzle | 260±10 °C |

| Heatbed | 110±5 °C |

Basic Attributes

Great for outside use – UV stable | Large models have a tendency to warp | ||

High temperature resistance | Produces odors during printing (less than ABS) | ||

Detailed prints without a stringing effect | Contains styrene | ||

Can be smoothed with acetone vapors | Hygroscopic | ||

Can be easily sanded / post-processed | Not recommended to print on the Textured powder-coated steel sheet - very strong adhesion may cause damage to the steel sheet surface | ||

High impact and wear resistance | |||

Recyclable |

Notes

This ASA is made in-house by Prusa Research.

1.75 mm filament is manufactured with a precision of +- 0.03 mm

Before printing, make sure the surface of heatbed is clean as described in 3D Printing Handbook.

To dry the filament, please follow the instructions in our article.Reviews

The Seller does not verify whether the published reviews come from consumers who have actually used or purchased the products or digital content or service. Reviews are provided by registered PRUSA ACCOUNT users.